Our Group organises 3000+ Global Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open 91桃色 Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open 91桃色 Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

Citations : 1089

Indexed In

- CAS Source Index (CASSI)

- Index Copernicus

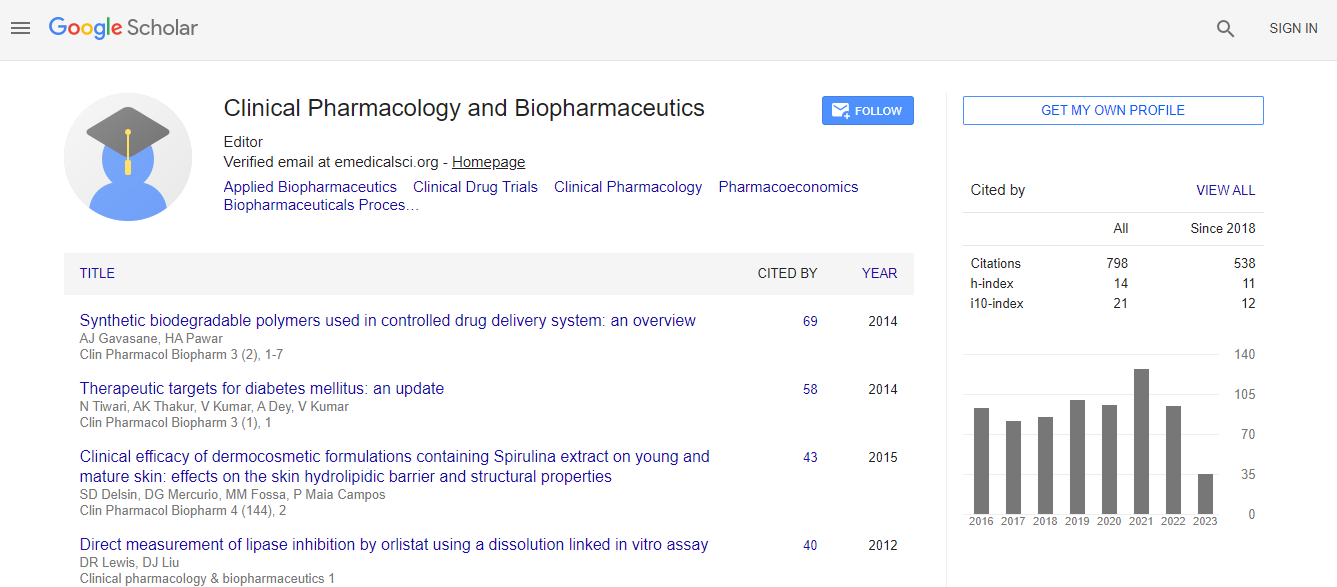

- Google Scholar

- Sherpa Romeo

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Enhancement of gum acacia solubility by single process of humidification and drying (granulation)

Pharma Middle East

Waddah F Nour1 and Suad Y Alkarib2

University of Karary, Sudan

Posters-Accepted Abstracts: Clin Pharmacol Biopharm

DOI:

Abstract

Introduction: Gum arabic is a complex, loose aggregate of sugars and hemicelluloses composed of arabic acid nucleus connected with calcium, magnesium, potassium and sugars arabinose, galactose, and rhamnose. It is found in mechanically ground or spray dried forms. The solubility varies between 2 hours in the raw gum form and 20 minutes in spray dried form. This study tended to enhance the solubility by producing an instant soluble granulated form. Methodology: The study was performed using atomized fluid bed drier. 50 kg of raw gum, subjected first to mechanical comminuting into powder, then treated with water by spraying at rate of 200 ml/min for 90 minutes. The inlet temperature was 70oC, and the outlet temperature was 40oC. The cabinet temperature was 40oC. Finally, after water treatment process, the powder resized through mesh size of 40 micrometer and the microbial test was done for the finished product. Results: The solubility of the granulated instant soluble gum in room temperature was found to be less than 2 minutes compared to the spray dried form which is 20 to 30 minutes and 2 hours for mechanical ground gum. The volume increased to three times compared to the mechanical form. Conclusions: Granulation of gum under water spray significantly enhances the solubility and hence it is beneficial for uses in pharmaceutical technology as a binder, suspending agent, surface active agent and tablet coating materials.Biography

Email: waddahfaroug@gmail.com